What is a BOPP Bag?

A BOPP bag is a packaging product made with BOPP film as the core material, where BOPP stands for “Biaxially Oriented Polypropylene” (English abbreviation). Its core structure usually consists of BOPP film compounded with other base materials (such as PP woven fabric, non-woven fabric, etc.). Common types include BOPP laminated PP woven bags, BOPP pearl film bags, BOPP transparent bags, etc. Through biaxial stretching technology, BOPP film has higher transparency, glossiness and mechanical strength, making the packaging both protective and displayable.

What are the Advantages of BOPP Bags?

With its composite structure and material properties, BOPP bags have multiple core advantages, suitable for multi-scenario packaging needs:

- Excellent Display Performance: BOPP film has high transparency and glossiness, which can clearly display the internal products. At the same time, it supports exquisite printing and improves the grade of product packaging;

- Strong Protection: It has excellent moisture resistance, stain resistance and puncture resistance, which can effectively protect the internal contents from the external environment and extend the product shelf life;

- Superior Mechanical Properties: Higher tensile strength and tear strength than ordinary plastic bags, stronger load-bearing capacity, suitable for long-distance transportation and warehouse stacking;

- High Cost-Effectiveness: Controllable material cost, mature production process, both high quality and economy, widely used in mid-to-high-end packaging scenarios;

- Flexible Application: Can be customized with different thicknesses, specifications and printing patterns according to needs, and can also be equipped with drawstring, self-adhesive sealing and other designs, suitable for various product packaging.

What are BOPP Bags Used For?

The application scenarios of BOPP bags cover multiple industries, mainly used for product packaging, storage and transportation, including:

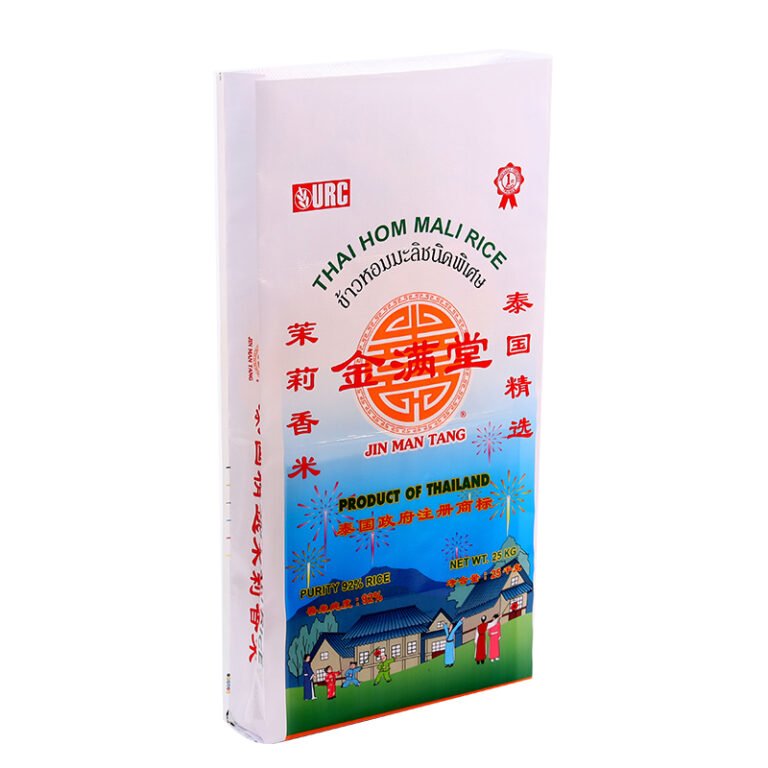

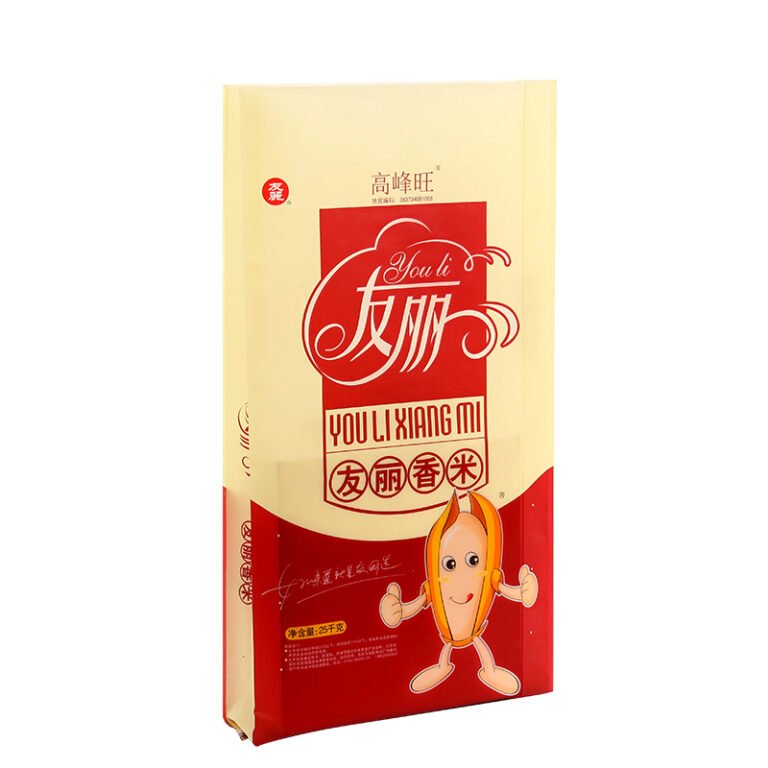

- Food Industry: Packaging snacks (potato chips, nuts, candies), grains, oils, teas, dried foods (agaric, shiitake mushrooms), etc. Transparent versions can display food shapes, and laminated versions have moisture-proof and fresh-keeping functions;

- Daily Necessities and Textile Industry: Packaging clothing, towels, bedding, tissues, cosmetic accessories, etc., to improve product display effect;

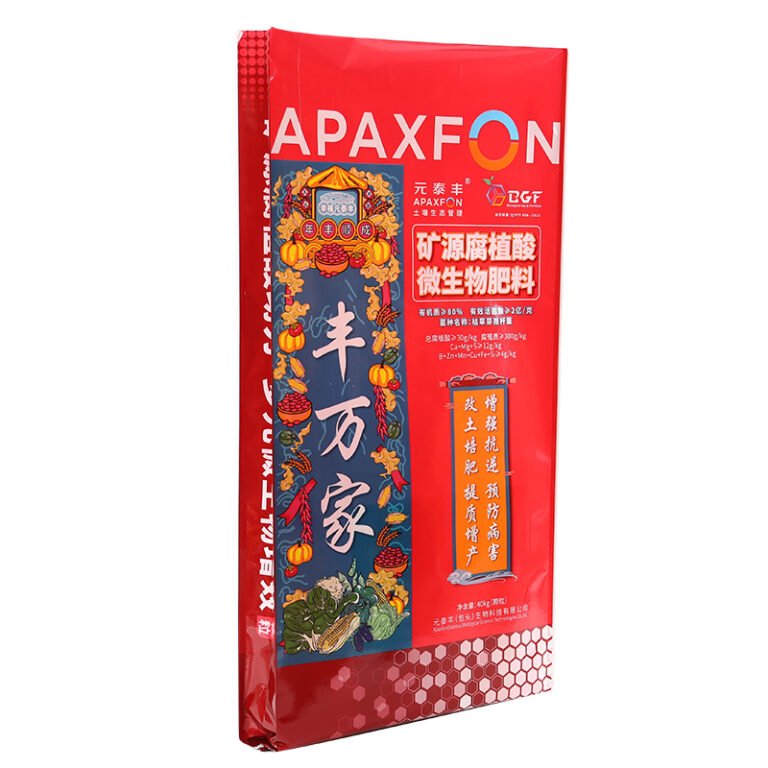

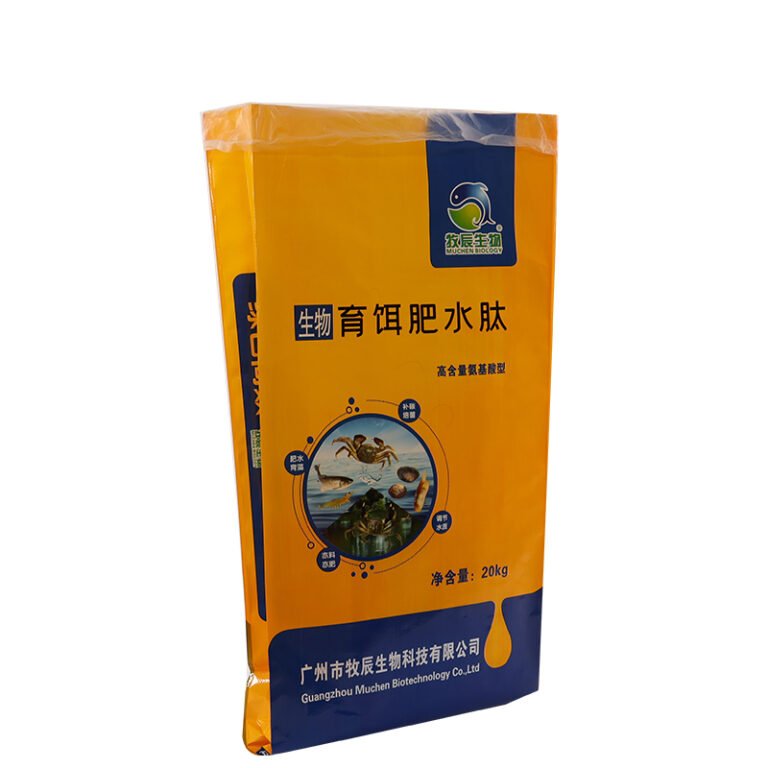

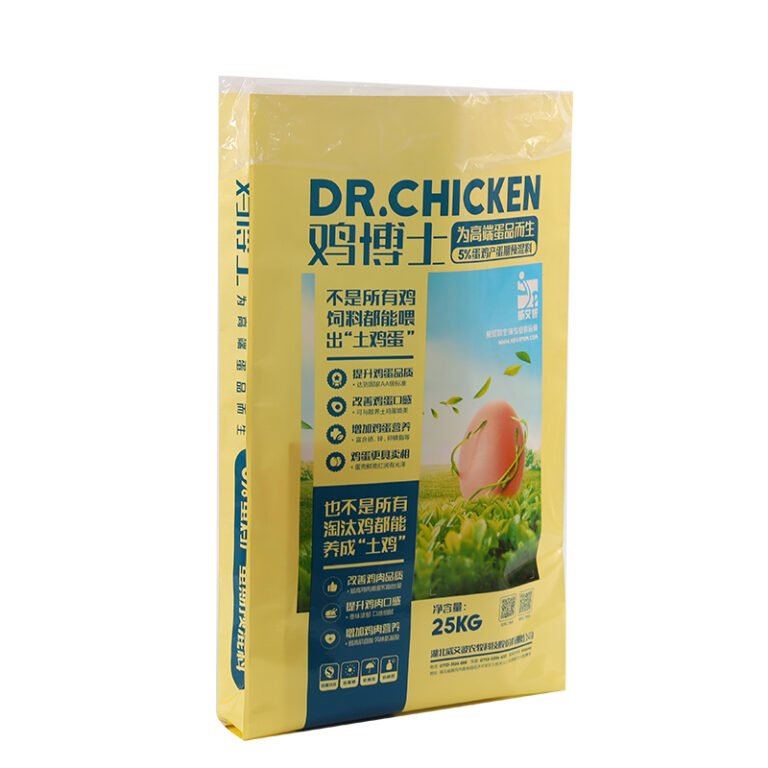

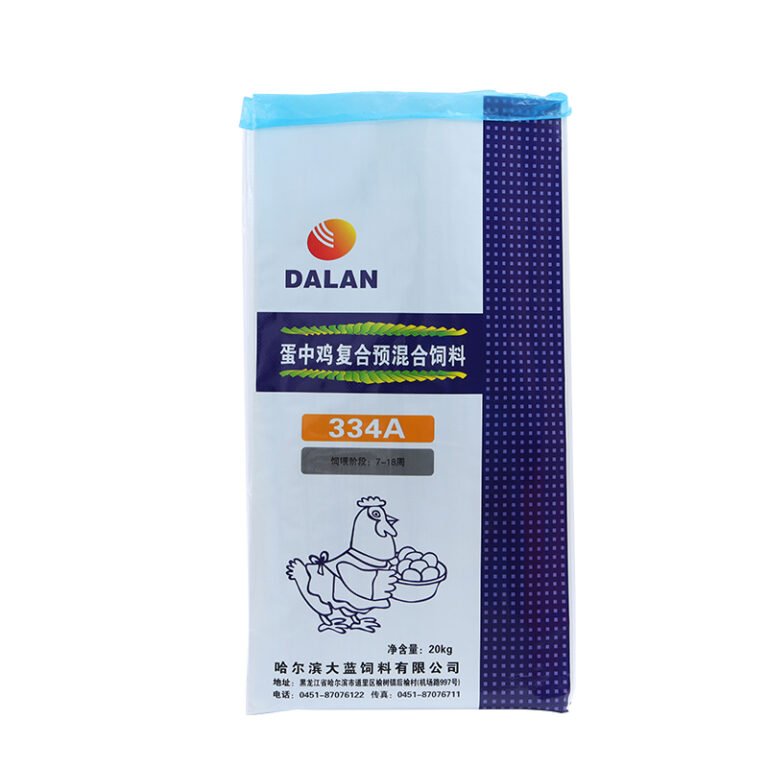

- Industrial and Agricultural Fields: Common BOPP laminated PP woven bags are used for packaging chemical fertilizers, feed, cement, plastic particles, etc., with both protective and printing marking functions;

- Logistics and E-commerce Fields: As outer packaging or inner packaging for commodities, protecting products from damage during transportation, and can print brand information and logistics marks at the same time.

Is BOPP Plastic Safe?

BOPP plastic that meets industry standards is safe and widely used in food packaging. The core material of BOPP is polypropylene, which is non-toxic, odorless, has strong chemical stability, does not contain harmful plasticizers, and meets the safety standards for food contact materials such as FDA (U.S. Food and Drug Administration) and EC (European Union).

Note: For BOPP bags used in food packaging, products made of “food-grade” raw materials should be selected to ensure that the production process complies with the hygiene standards for food contact materials; at the same time, avoid long-term storage of high-temperature food (the melting point of polypropylene is about 167℃, which is safe for use at room temperature, and may deform in high-temperature environments).

Can BOPP Bags Be Recycled?

Yes, they can be recycled. The core material of BOPP bags is polypropylene (PP), which belongs to the recyclable plastic category (recycling symbol “5”). Recycled BOPP bags can be reprocessed into plastic particles through crushing, cleaning, granulation and other processes, which are used to produce recycled plastic products (such as plastic basins, trash cans, recycled PP woven fabrics, etc.).

Warm Reminder: When recycling, it is recommended to separate different base materials in BOPP composite bags (such as BOPP film and PP woven fabric) as much as possible, or choose BOPP bags made of a single PP material, which can improve recycling efficiency and recycling value; at the same time, avoid mixing heavily polluted BOPP bags (such as those stained with oil, chemicals) into the recycling system.

Are BOPP Laminated PP Woven Bags 100% Biodegradable?

No. The core material of BOPP laminated PP woven bags (i.e., BOPP coated PP woven bags) is polypropylene (PP), which is a petroleum-based plastic. Its natural degradation cycle is extremely long (up to hundreds of years), and it cannot achieve 100% biodegradation.

If there are environmental protection needs, modified products added with “degradable masterbatch” (such as PBAT/PLA composite degradable materials) can be selected. However, their degradation requires specific temperature, humidity and microbial environments (such as industrial composting conditions), and the cost is relatively high; conventional commercial BOPP laminated PP woven bags do not have biodegradable properties. It is recommended to achieve environmental protection cycle through recycling and reuse.

+Qianfu has produced in Pp woven bags for 25 years

As one of the leading bag manufacture in China.